Food processing

Lösungen

Frische Rohstoffe, die nicht direkt an den Verbrauchermarkt gehen, erzeugen lebensmitteltaugliche Überreste, die zu Futtermitteln weiterverarbeitet werden können. Das bedeutet weniger Ertrags- und Produktionsausfall. Haarslev hilft Ihnen, Überreste in eine wertvolle Einnahmequelle zu verwandeln, indem sie in hochwertige Proteinpulverprodukte für den Lebensmittel- oder Fleischmarkt oder in einen hochwertigen Inhaltsstoff für die Heimtiernahrungsindustrie verarbeitet werden.

Lösungen

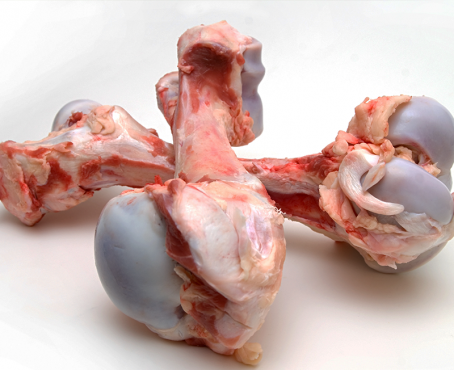

Suitable raw materials are: fresh poultry meat and bone leftovers, mechanically deboned products, animal bones, connective and fat trimmings and seafood by-products.

Geflügel

Verarbeitung

From the poultry application fresh meat cuts, trimming or carcass can be collected and chilled before they are processed into flavour soup extract or broth product. The final product can be concentrated liquid and can be sold in chilled form or dried into a powder with outstanding taste, nutrition and 100% solubility.

Available process solutions-

Digestion BONE EXTRACT Processing Line

A continuous digestion process engineered system for meat and bone material to customer specification from low to medium capacity.

-

BONE SOUP (BROTH ) Processing Line

A continuous pressure cooking process engineered system for meat and bone material to customer specification from low to medium capacity.

BONE

VERARBEITUNG

From the deboning rooms in a slaughtering or meat producer's plant, fresh meat cuts, trimming or bone leftovers are collected and turned into a food ingredient or a meat substitute final product. The final liquid product is concentrated and can be sold in chilled form or dried into a powder with good functionalities and nutrition value.

AVAILABLE PROCESS SOLUTIONS-

Digestion BONE EXTRACT Processing Line

A continuous digestion process engineered system for meat and bone material to customer specification from low to medium capacity.

-

BONE SOUP Cooking Processing Line

A continuous pressure cooking process engineered system for meat and bone material to customer specification from low to medium capacity.

FAT AND PROTEIN

VERARBEITUNG

From the deboning rooms in a slaughtering or meat producer’s plant, fresh trimming cuts and fat leftovers are collected and turn into a food grade edible lard or tallow and an edible protein meat as substitute final product with enhanced functionalities.

AVAILABLE PROCESS SOLUTIONS-

Fat and Melting Processing Line

A continuous engineered system to process fatty cut off and trimming material into food grade fat and functional edible protein to customer specification from low to high capacity.

FISH OIL

VERARBEITUNG

From the seafood application fresh head frame and fish skin and partly organs can be pumped to a process line to make high grade fish oil for food or nutraceutical purpose. Extreme fresh raw material like liver can be processed in a few minutes, which offers a high-grade fish oil product like COD liver or other fish enriched with EPA and DHE content.

AVAILABLE PROCESS SOLUTIONS-

Ultra Short Processing Line

A continuous processing modulated to make high-grade fish oil.

Vorsorgen

für das Morgen

Haarslev Global Services sorgt dafür, dass Ihr Unternehmen Fortschritte macht

Ausfallzeiten sind für jedes Unternehmen desaströs und müssen um jeden Preis vermieden werden. Unsere Systeme wurden entwickelt, um Ihnen eine maximale Maschinenverfügbarkeit zu garantieren.

Die Abteilung Haarslev Global Services unterstützt Sie beim zuverlässigen, effizienten und profitablen Betrieb Ihrer Anlage an jedem Tag des Jahres.

Umfassend geschulte Experten geben Ihnen professionellen Rat zu Ihren Prozessen und zur Umsetzung der richtigen Abläufe für die Wartung und die Lagerung von Ersatzteilen. Sie können dadurch:

- Ihre Durchlaufleistung gewährleisten

- mehr Ausbeute pro Produkt erzielen

- die Gesamtbetriebskosten (TOC) verringern